The main characteristics of boron carbide:

1. High melting point

2. Large neutron capture

3. Low density

4. Better chemical inertness

5. Excellent thermal properties

6. Excellent electrical properties

As a new type of ceramic, boron carbide ceramics have high wear resistance and high hardness structure and have been used in military and aviation fields.

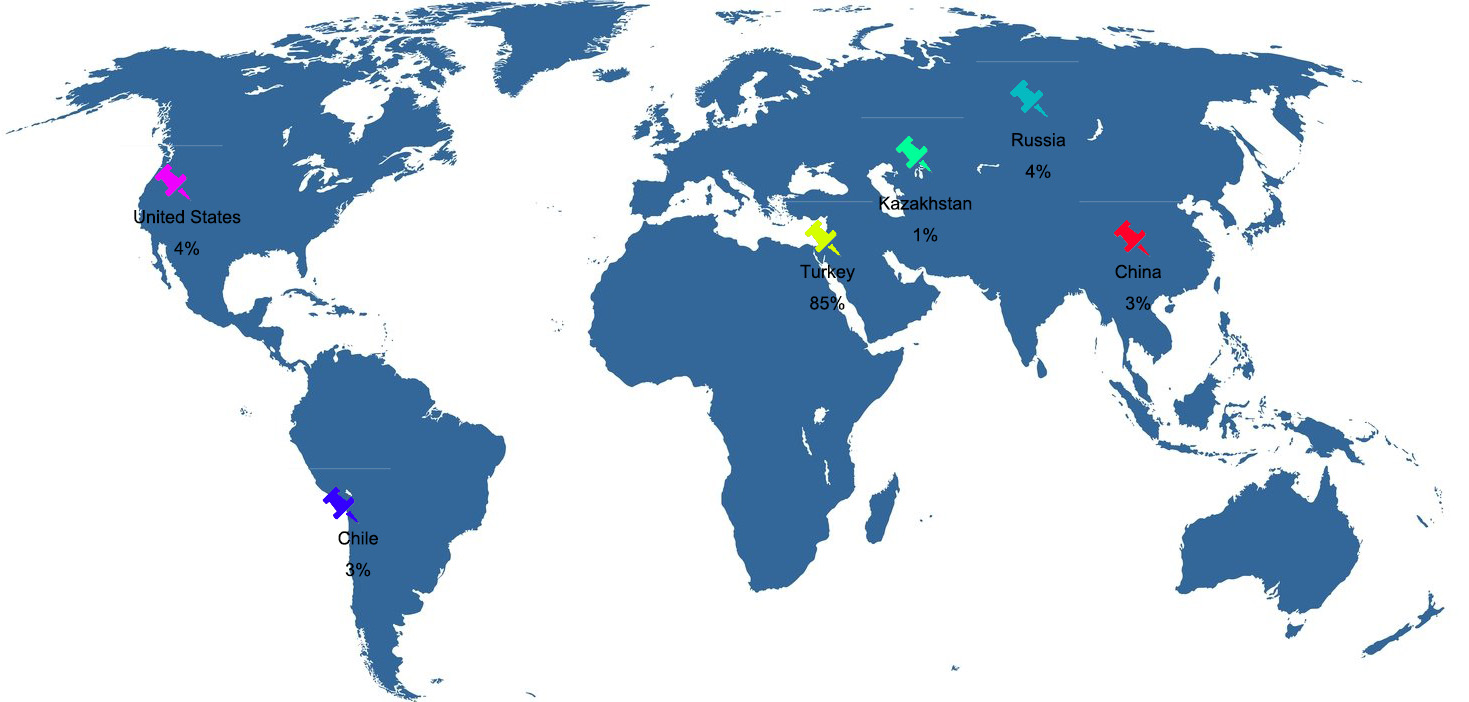

The main distribution countries of boron carbide resources in the world are Turkey, the United States, Russia, Chile and China.

According to statistics from the US Geological Service, the global boron resource reserves in 2017 reached 1.1 billion tons, of which Turkey had 950 million tons.

Boron carbide properties:

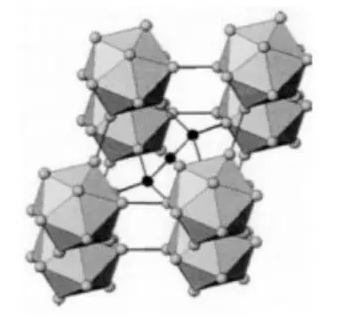

1. Crystal structure: hexagonal rhombohedral structure

2. Physical properties:

High hardness P-type semiconductor

Strong impact absorption

high melting point

high elasticity

low expansion

good oxygen absorption capacity

3. Chemical properties: Boron carbide will not react with acids, alkalis and most inorganic compounds at room temperature, hardly react with oxygen at room temperature, and its chemical properties are stable.

Production of boron carbide powder

1. Carbothermal reduction method: use electric arc furnace for high-temperature reduction reaction, the chemical formula is:

2B2O3+7C=B4C+6CO

4H3BO3+7C=B4C+6CO+6H2O

2.Self-propagating High-temperature Synthesis

Using SHS technology, a technology for synthesizing materials by utilizing the self-heating and self-conducting effects of high chemical reactions between reactants.

3.Chemical vapor deposition (CVD)

At a higher temperature, the mixed gas interacts with the surface of the substrate to decompose some components of the gas and form a thin film on the substrate.

Firing of boron carbide

1. Hot pressing sintering

At present, the most used method is to pack the powder in the mold, and apply a certain pressure to the powder while heating. However, this method has strict control over production, high cost and low production efficiency. .

2. Pressureless sintering

Parts with complex shapes can be fired, the production cost is low, and the operation is simple, but the performance of the finished product is poor, and the product is easy to crack during the firing process.

3. Spark plasma sintering

4. Microwave sintering

Application areas:

Bulletproof armor field: Boron carbide ceramics have the characteristics of light weight and ultra-high hardness, and are the best material for bulletproof inserts and bulletproof shields.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish