With the improvement of the penetration of weapons and ammunition and the progress and development of protective material technology, the corresponding bulletproof standards of various countries have been properly adjusted and improved to make them more in line with the protection requirements under the new situation. Therefore, understanding and mastering the latest bulletproof standards and technical requirements in different countries is of great significance for researchers engaged in related industries. At present, there are three main methods for evaluating the ballistic performance of armor protection materials: the first is to classify the bullet resistance of materials according to the degree of bullet resistance; the second is to measure the protection coefficient; the third is to determine the limit of protective materials Penetration speed.

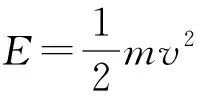

In the formula: is the mass of the bullet; is the velocity of the bullet. The distance between the muzzle and the speed measuring device is relatively close, and the speed change caused by wind resistance is small. Therefore, the standard bullet velocity is used as the initial velocity of the muzzle to calculate the initial kinetic energy.

1. Research and comparison of commonly used bulletproof standards

1.1 Body armor standards

Body armor is the most important part of the individual (police) protection system, helping the wearer to resist the penetration of projectiles and fragments. The prototype of modern body armor is a simple combination of natural fiber and silk bulletproof vests during World War I and manganese steel sheets and linen during World War II. With the development and progress of the protective performance of body armor, how to evaluate its protective ability has become an urgent problem to be solved. The bulletproof standard is formulated and continuously revised and improved under the background of this demand.

1.1.1 NIJ 0101.06 body armor standard

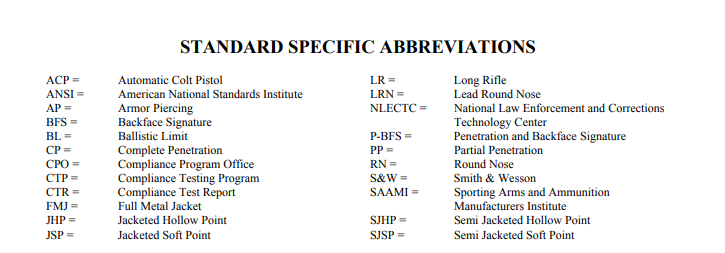

The United States is the country with the largest number of private guns in the world, and the resulting shooting rate is very high. The NIJ 0101.06 bulletproof standard for body armor released by the National Institute of Justice in 2008 has become one of the most widely used standards for the evaluation of body armor protection in the world. Most of the body armor exported from my country is tested and evaluated according to this standard.

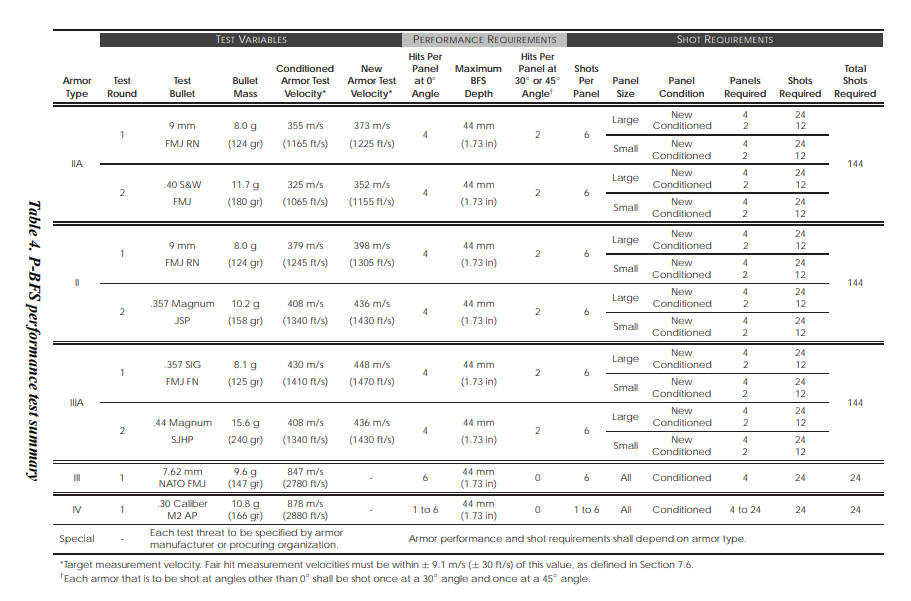

The NIJ 0101.06 bulletproof standard protection grade classification and related test conditions are shown in Table 2. This standard divides the protection performance into 5 grades (special tests are not included in the grade classification), which are respectively class ⅡA, class Ⅱ, Level ⅢA, level Ⅲ and level Ⅳ against the threat of rifle projectiles, canceled the minimum protection level Ⅰ in the NIJ0101.04A standard. The standard stipulates that all the two types of bullets listed in the same protection level are tested. For example, the two types of projectiles tested in the IIA level are 9×19 mm all-metal armor round-head lead core bullet and .40 S&W all-metal armor flat-head lead Heart bullet, the structure of the two warheads is different, so the armor-piercing damage effect is also different. Since the bulletproof performance of the material has a certain relationship with its own temperature, most bulletproof standards require that the protective equipment tested need to undergo an environmental adaptability experiment. Ballistic performance of body armor after such treatment. The NIJ 0101.06 standard requires the number, size and type of test samples and the position of the impact point. The sample size of the insert plate in the hard body armor is ≤254 mm×305 mm.

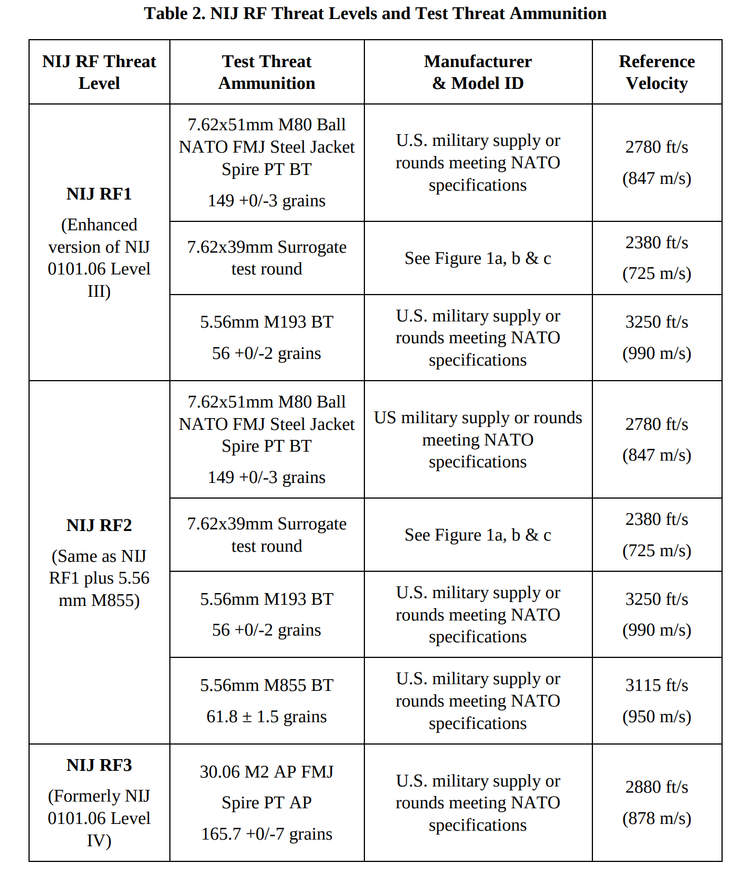

1.1.2 NIJ 0101.07 Body Armor Standard

The NIJ 0101.07 draft standard for body armor was released in 2018 and reviewed for public review, aiming to replace the NIJ 0101.06 standard for body armor. The new version of the standard divides body armor into two categories: anti-pistol bullet HG level and anti-rifle bullet RF level. The initial kinetic energy of the projectile ranges from the lowest protection level of 634 J to the highest protection level of 4124 J. The classification of each protection level and related shooting requirements are shown in Table 3. In the NIJ 0101.07 standard, the bullet speed difference between old and new bulletproof vests is cancelled, and all high bullet speeds are adopted. In addition, the ⅡA level in the NIJ 0101.06 standard has been cancelled. Compared with NIJ 0101.06, the new standard has increased the types of test rifle projectiles. The body armor of the RF1 level needs to test the shooting experiments of M80, M43, and M193. The three types of projectiles have all High-power projectiles with high kinetic energy and high-penetration projectiles require that the protection level of body armor should not only be able to resist full-power projectiles, but also be able to resist intermediate-power projectiles and high-penetration projectiles. getting stricter. The RF2 level body armor adds the SS109 projectile test on the basis of the RF1 level. The projectile is the same size as the M193 projectile, but the internal structure and core material are different. SS109 is a pointed steel bullet with a lead core base and has excellent penetration. on M193. Both the old and new standards have the highest level of protection required to be able to resist the penetration of the .30-06 M2 all-metal copper jacket pointed armor-piercing bullet. The core material of the bullet is a hard steel core with a hardness of 785 HV. In addition, the target test results require that there are no visible transparent cracks in the crater, and the maximum back mark depression depth is ≤44 mm.

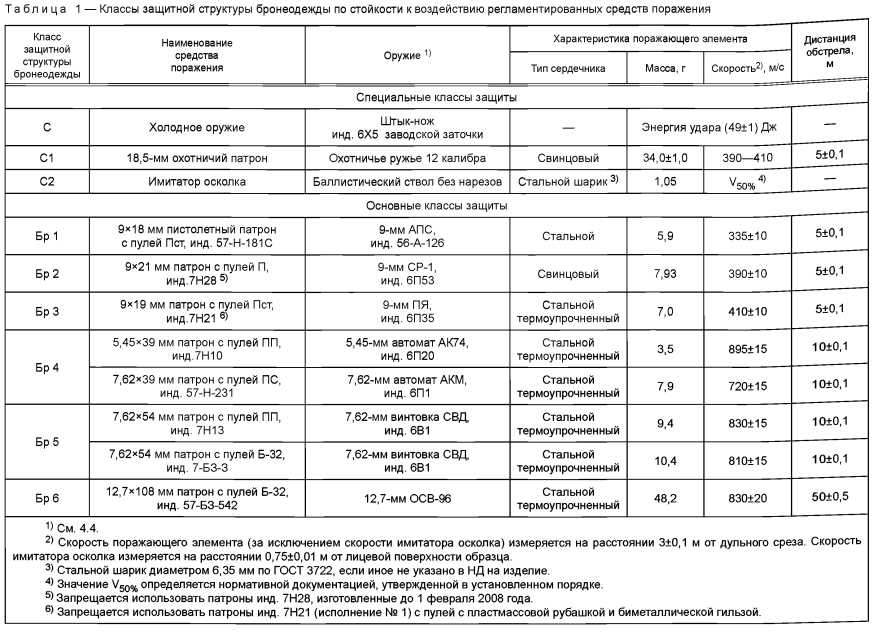

1.1.3 GOST 34286-2017 Classification and general specifications of body armor

Russian GOST 34286-2017 body armor classification and general specifications were released in 2017. This standard divides the body armor bulletproof capability into 6 grades, BR1 to BR6, as shown in Table 4. This standard also grades the anti-stab, anti-shotgun, and anti-fragmentation capabilities of body armor, and the grade codes are S-level, S1-level and S2-level respectively. In the standard, BR1 to BR3 are the protection levels against the threat of pistols, and the three levels require that the depth of the back substrate material depression after the test sample is effectively hit is ≤17 mm. Since the BR3-level test projectile uses a reinforced steel core bullet with higher hardness, even though the kinetic energy of the projectile is lower than that of the BR2-level test projectile, the protection level is higher. BR4 to BR6 are the protection levels against the threat of rifles. The bulletproof performance of these three levels in the new standard requires that the target plate does not penetrate, and there is no requirement for the depth of the depression of the substrate material on the back of the target plate. The highest protection level of this standard is BR6, and the tested projectile is a 12.7×108 mm all-metal steel armor-piercing incendiary projectile with an initial kinetic energy of 16 602 J, which is the highest protection level among all current body armor standards.

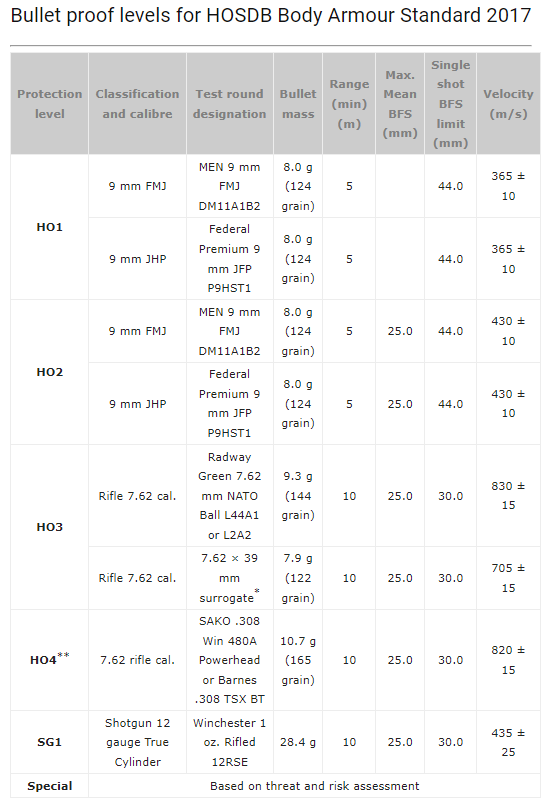

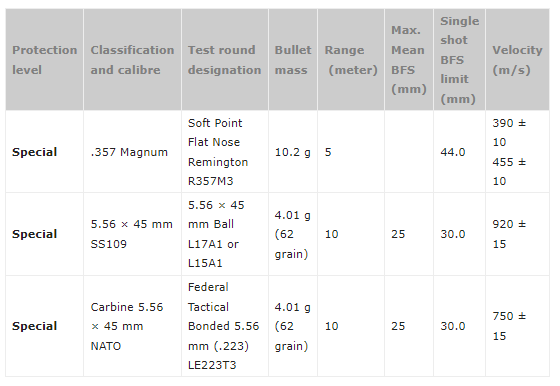

1.1.4 HOSDB-2017 Police body armor standard

The British Ministry of Home Affairs and Scientific Development issued the first edition of the police body armor standard in 1993. After more than 20 years of revision and improvement, the latest body armor standard was released in 2017. The standard divides the body armor protection level into HO1~HO4 four 357 Magnum and SS109 projectiles are listed as special levels, as shown in Table 5. HO1 and HO2 level body armor are used to resist the threat of pistol projectiles. These two levels of defense have the same type of bullets and different bullet speeds. HO3, HO4 level body armor is used to resist the threat of rifle projectiles. Compared with the 2007 version of the bulletproof standard, the new standard HO3 grade has added the test of AK47 shooting M43 projectiles (7.62×39 mm). The highest protection level HO4 test projectile is 7.62×51 mm SAKO .308Win 480A POWERHEAD all-copper open-tip projectile. During the process, the auxiliary warhead expands, and the warhead has a special structure, as shown in Figure 1. The 3 weapons and ammunition in the special class are not listed in the British police force, so they are classified as special class. The requirements of this standard for the depth of back marks on the target plate vary with different protection levels, as shown in Table.

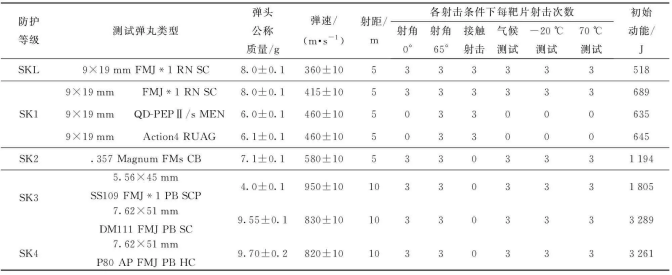

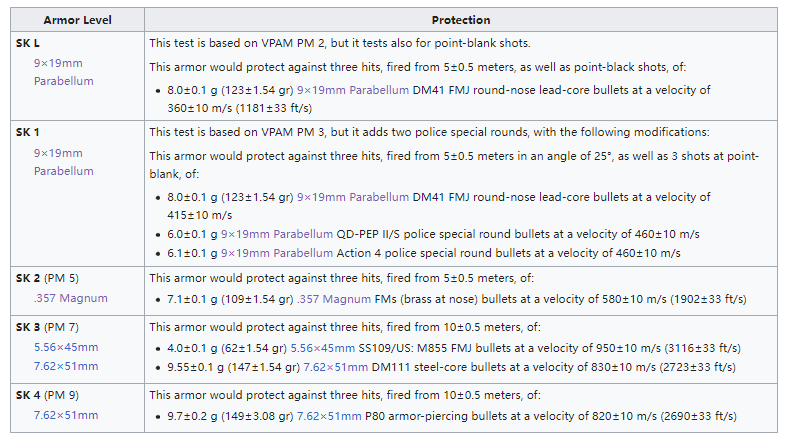

1.1.5 SCHUTZKLASS Body Armor Standard 2008 Edition

The 2008 version of the SCHUTZKLASS bulletproof vest standard is one of the most widely used bulletproof standards in Germany. This standard divides the bulletproof capabilities of bulletproof vests and inserts into five grades from SKL to SK4. The classification and shooting conditions of each grade are shown in Table 6. The size requirement of the bulletproof vest test sample is 350 mm×400 mm. This standard does not have the requirement of shooting after the sample is immersed in water, but has the requirement of contact shooting test, which is different from other bulletproof standards. The ballistic performance requires that the projectile does not penetrate the sample, no visible cracks appear in the crater, and the depth of the bullet marks on the back of the sample is less than 42 mm.

1.1.6 GA 141-2010 Police body armor

Compared with countries such as Europe and the United States, the formulation of bulletproof standards in my country started a little later, but after more than 20 years of development, it has been relatively complete. The current version of the body armor standard is the GA 141-2010 "Police Body Armor" standard released in 2010. This standard divides the protection level of body armor into 6 levels, as shown in Table 7, and specifies the test methods and inspection rules for body armor. Detailed requirements have been made. The projectiles tested for protection levels 1 to 4 are all pistol projectiles, and the initial kinetic energy is between 249 and 753 J. The size and structure of the projectiles tested for protection levels 3 and 4 are the same, but the core materials of the two are different. The level 3 protection test projectile is a steel core bullet, and its penetration ability is better than that of the level 3 protection test projectile with the same initial kinetic energy. The level 5 protection test projectile is a 7.62×39 mm all-metal copper-clad steel jacket pointed steel core projectile with an initial kinetic energy of 2 116 J, which is close to the RF1 level in NIJ 0101.07. The level 6 protection test projectile is a 7.62×54 mm all-metal copper-clad steel jacket pointed steel core projectile, and the initial kinetic energy of the projectile is 3 307 J. This standard requires that the ballistic performance of the sample is that all bullets do not penetrate the body armor, there is no visible through crack, and the depth of the back mark is ≤25 mm, which is lower than the depth of the back mark in the US NIJ0101.06 standard (≤44 mm). After the test sample is pretreated in high and low temperature and soaked in hot and humid environment, it is called old body armor. The water immersion test lasted 30 min, the high temperature test temperature was 70 ℃ ± 2 ℃, the relative humidity was 80%, and the treatment time was 240 h.

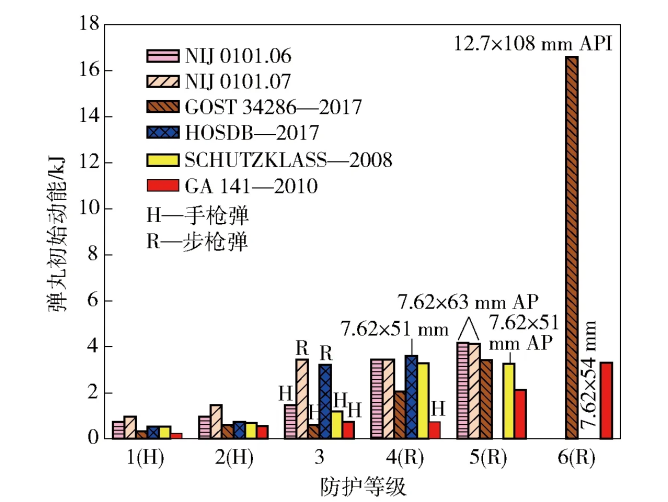

1.1.7 Comparison and analysis of protection levels

Taking the protection level as the abscissa and the initial kinetic energy of the projectile as the ordinate, compare and analyze the initial kinetic energy of the penetrating projectile for each protection level of the above six commonly used body armor standards. The results are shown in the figure below. 3 types of bullets, the maximum kinetic energy of these types of bullets was used for comparison, and the protection levels of shotguns, shotguns, and fragments were not included in the figure.

From the point of view of the initial kinetic energy of the projectile, the highest level of protection in the current bulletproof standards for body armor is level 6 protection in the Russian GOST 34286-2017 standard. The mass is 48.2 g, and the initial kinetic energy of the projectile is 16 602 J, which is obviously higher than the initial kinetic energy of the test projectile in other standards; followed by the RF3 level in the US NIJ 0101.07 standard and the IV level in NIJ 0101.06, the test projectiles are all .30-06 The armor-piercing projectile with metal copper armor and pointed tip has a projectile size of 7.62×63 mm, a projectile mass of 10.7 g±0.1 g, and an initial kinetic energy of 4 124 to 4 163 J. my country’s GA 141-2010 standard has the highest level of protection level 6 test bullet for the Type 79/85 sniper rifle, which fires a Type 53 7.62×54 mm all-metal steel armored pointed steel core bullet with a bullet mass of 9.6 g and an initial kinetic energy of 3 307 J. Figure 2 shows that the initial kinetic energy of the projectiles tested for each protection level of pistols and rifles in my country's bulletproof standards is lower than that of foreign countries.

From the perspective of the structure and material of the test projectiles of each level, the test projectiles of China, Russia and Germany mostly use all-metal copper-clad steel armor projectiles, and most of the Russian test projectiles have reinforced steel core projectiles, which have higher hardness and stronger penetrating ability. Moreover, the BR5-BR6 test projectiles use armor-piercing incendiary bombs containing incendiary agents, which have greater armor-piercing damage. Most of the test projectiles in my country are made of low-carbon steel, and the hardness of the projectile is relatively low. In the tests of various levels of bulletproof standards in the United Kingdom and the United States, all-metal copper-coated projectiles are mostly used. The projectile core is mostly made of lead alloy, and the hardness is low. The Russian GOST 34286-2017 standard tests the armor-piercing projectile of the 9×19 mm pistol projectile in the BR3 protection level. Although the initial kinetic energy of the projectile is only 588 J, its core hardness is high and the penetration ability is good, so the threat level is higher than that of other standards. Level pistol pellets.

Comparing the protection levels of body armor standards in various countries, the level 5 protection ability of China's GA 141-2010 standard is between the ⅢA level and Ⅲ level of the NIJ 0101.06 standard, close to the RF1 level of the NIJ 0101.07 standard and the HO3 level of the HOSDB-2017 standard. Slightly lower than the BR4 level of the GOST 34286-2017 standard; the level 6 protection ability in the GA 141-2010 standard is close to the RF2 level in the NIJ 0101.07 standard and the SK3 level in the German SCHUTZKLASS-2008 standard, which is between the BR4 in the GOST 34286-2017 standard Between the BR5 level and lower than the HO4 level in the HOSDB-2017 standard. The test projectile with the highest protection level in my country's military body armor standard GJB 4300A—2012 is a 7.62×54 mm armor-piercing incendiary projectile with a warhead mass of 10.45 g and an initial kinetic energy of 3 428 J. This level of protection is close to the RF3 level in the NIJ 0101.07 standard , the BR5 grade in the GOST 34286-2017 standard is better than the HO4 grade in the HOSDB-2017 standard and the SK4 grade in the SCHUTZKLASS-2008 standard. In addition to the above six bulletproof standards, the STANAG 2920 personal armor material and ballistic test method for body armor formulated and released by NATO is also a commonly used bulletproof standard. Value, no protection level division, so this article does not include the standard in the comparative analysis.

Through the above comparison and analysis, it can be seen that the initial kinetic energy of the test projectiles of each protection level in my country’s GA 141-2010 standard is lower than that of the same level of test projectiles in other countries’ bulletproof standards, and the types of test projectiles of the same level are also less than those of foreign bulletproof standards. Part of the reason is that The difference is caused by factors such as the type of standard bullets at home and abroad, the number of privately owned guns, the incidence of shooting cases, and the environment in which protective equipment is used.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish